Making An Acoustic Guitar Saddle

The saddle is a vital part of an acoustic guitar. Protruding above the bridge, it is one of the primary action adjustment points for the instrument. Without a well made saddle, proper setup will not be possible. Though they can be made from many different materials, for this article, we will be focusing on the process of hand cutting a new acoustic guitar saddle out of a piece of bone.

Making A Compensated Bone Saddle: Step By Step

Measuring A Blank

We begin with a suitable bone blank that is sufficiently oversized relative to the existing saddle slot on the instrument’s bridge.

Using a measuring tool called a caliper, we measure the length of the saddle slot then mark the desired length on our saddle blank.

The saddle is cut roughly to length using a saw.

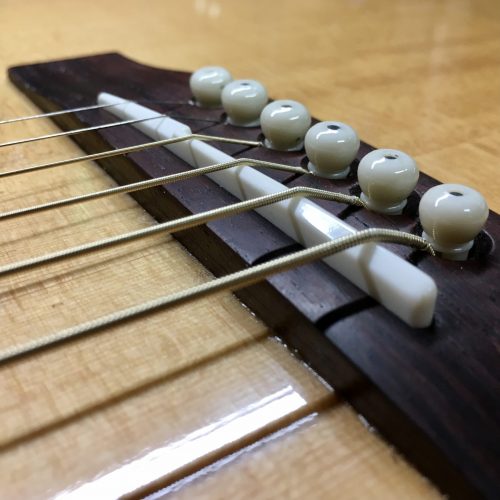

Fitting The Saddle To The Slot

We carefully shape the blank, adjusting the length, width, and rounding the edges, until the piece is properly seated in the saddle slot. A poorly fit saddle can eventually cause the wooden saddle slot to crack. A correct fit should be snug, but not excessively difficult to remove.

Instruments with under-saddle pickups may require some extra finesse to ensure that the bottom of the saddle rests firmly against the pickup that is installed on the bottom of the saddle slot.

Radiusing The Saddle

After measuring the fingerboard’s radius (curvature), we use our radius gauge to draw the profile of the fingerboard onto the saddle blank. Then it’s over to a disc sander to remove material, sanding a matching contour on the saddle’s top.

Compensating The Saddle

“Compensation” is a term to describe adjustments made to the functional length of the string in order to fine-tune the intonation of the instrument.

To accomplish this, we first mark the saddle between the second and third string since this marks the switch from plain to wound strings in a standard acoustic string set.

Then we draw two lines diagonally across the length of the saddle. These will serve as a guide of where to file. We then shape the top of the saddle, removing material on either side, until the desired compensation has been achieved.

Had we been making a traditional saddle, without string compensation, the top would simply have been rounded over to produce a crown across the length of the saddle. Compensation is a bit more work but yields better intonation in the instruments upper register.

Setting The Saddle Height

Back over to the guitar, we install the outer two strings to take an action measurement. If needed, we will perform additional sanding to achieve the desired string height we are seeking.

Polishing The Saddle

Once the action and intonation have been set, we use sandpaper to remove any rough tooling marks before switching to a dedicated buffing wheel to polish the saddle to a high shine. Besides aesthetic appeal, this provides a smooth surface for the string to rest against.

With that completed, the saddle is ready to go. It’s time to finish the setup and make some music!

Erik Salomon - Calico Guitarworks Owner / Head Technician

Tech Talk articles are part of an ongoing effort to provide clear and detailed answers to common questions about guitar maintenance, modifications, and repairs.

While not intended as a step-by-step guide to servicing your own instrument, we hope that you will find value in the information provided.

Great Repairs Start With The Right Parts

Many of the parts mentioned in our blogs are available for purchase at:

GuitarRepairParts.com

Enter the code "TechTalk10" at checkout for 10% off your first order.

About Calico Guitarworks

Calico Guitarworks is the area’s premier destination for fretted musical instrument care and maintenance. Owned and managed by Erik Salomon, the shop is dedicated to providing quick, honest and reliable service. The staff at Calico Guitarworks has a combined 25+ years of professional guitar repair experience. Sharing the knowledge that we accumulate in this focused pursuit is at the core of what we do. Learn more About Calico Guitarworks, explore our Frequently Asked Questions, or Contact us with a specific request.