String Nuts and Acoustic Guitar Saddles

In this article we will be discussing guitar string nuts, as well as acoustic guitar saddles. We have grouped these two items together because they work hand in hand with one another and are often made from similar materials.

What is A String Nut?

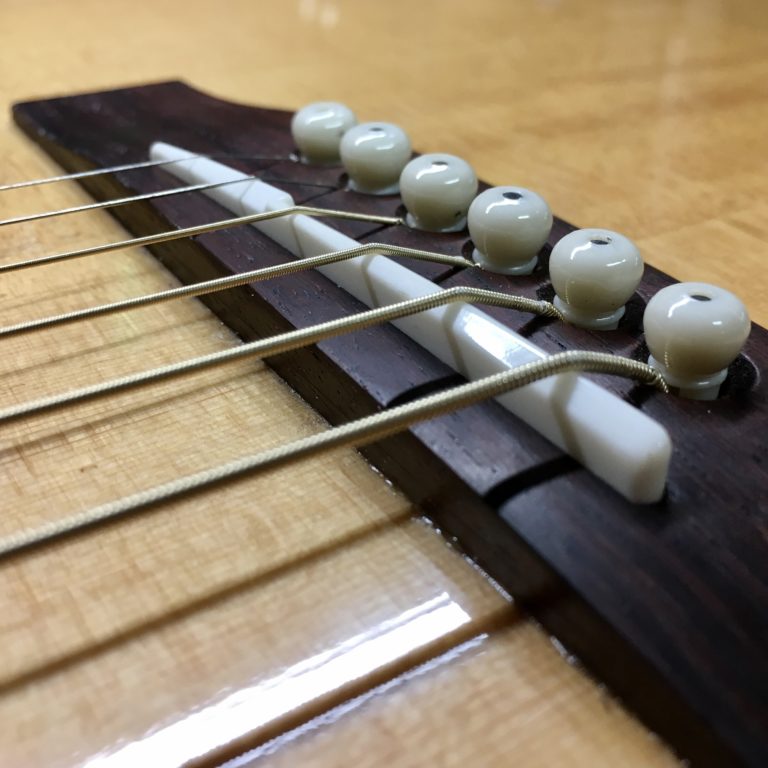

An instrument’s string nut, commonly called simply “the nut”, is a piece of hard material that is used to suspend and position the strings.

It is located on the neck, at the end of the fingerboard, at the base of the headplate, marking one end of the vibrating length of the strings.

The nut is notched to secure each string and set the width of the instrument’s string spacing. The depth of these notches is also typically used to set the height of the strings above the first fret.

Its proper fit and adjustment plays a crucial role in the guitar’s setup and playability. Over the course of an instrument’s life, string nuts may require replacement due to either wear and tear or player preference. Whether hand made or pre-slotted it is crucial that it be properly installed, and dressed.

Common Signs of Nut Issues May Include:

- Open String Buzzing

- Poor tuning stability.

- Difficulty playing open position chords

- "Pinging" sound when tuning

- String spacing issues - too wide or close

- "dead" sound from open strings

What is an Acoustic Guitar Saddle?

The saddle is a crucial part of an acoustic guitar. This thin strip protruding from the top of the bridge is responsible for suspending the strings and transmitting their vibration to the guitar’s top. It also helps to control the string action and intonation.

Whether hand made or pre-fabricated, for the best sound and most comfortable playing experience, it is important that a saddle be well fit and adjusted. A poorly fit saddle can eventually lead to bridge cracks or other structural issues.

Common Saddle Issues May Include:

- Worn - string groves

- String breakage at saddle

- Poor fit to the bridge slot

- No compensation - poor intonation

- Radius mismatched to fingerboard

- Soft material - kills tone and volume

- Action too low in the upper register

Any of the symptoms listed are typically grounds for replacement on their own.

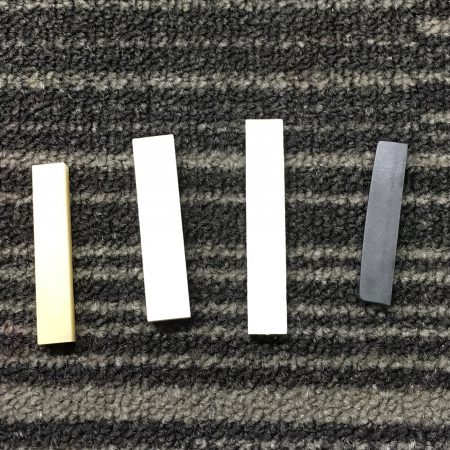

Common Nut and Saddle Materials

String Nuts and saddles can be made from a wide variety of different materials. The substance chosen will impact the look and tone of an instrument. Below are some of the common options.

Bone has a long history of use in musical instruments and is considered a benchmark material for guitar nuts and saddles. It works well, polishes to a high shine, and has a good hardness relative to its weight.

Common labels associated with this material type are “Bleached” and “Unbleached” / “vintage” bone. Bleached bone is more common in production instruments and has a uniform white appearance. The latter two terms are used interchangably and refer to a bone that has been through a bit less processing. It has an aged, dull yellow color that can look right at home on a vintage instrument.

The material is a byproduct of food production. It is typically produced from cattle remains sourced from Asia and India. A critique of the material, ethical concerns aside, is that it does not have a uniform consistency. The material can be prone to soft or weak spots as well as discolorations.

Graph Tech’s “Tusq” is probably the most widely requested aftermarket nut. While the name is a nod to the traditional use of ivory for instrument nuts and saddles, it is a completely synthetic polymer.

In recent years the product has fast become the industry standard. Their nuts and saddles have been used by just about every major guitar manufacturer. Calico Guitarworks is among their authorized dealers.

The standard Tusq material has an ivory color when new, but takes on a more yellow/orange appearance as it ages. Tusq nuts and saddles are available in a variety of different preformed and blank configurations. Their “Black tusq” nuts and saddles are a great option for someone wanting the look of black material.

Nubone is a derivative of Graph Tech’s proprietary “Tusq” material. The retail price is comparatively cheaper and in use we find that it is softer than tusq.

“Micarta” is a term that is used generically to refer to a wide variety of resin impregnated fiber compounds.

Martin has used Micarta nuts and saddles on many of their instruments since the 60’s. These nuts and saddles are ivory colored in appearance.

Taylor Guitars began primarily using Micarta saddles in 2014 when they introduced their ES2 expression system electronics.

Corian is an acrylic polymer that was originally produced by the Dupont Corporation. It is popular as a counter and tabletop surface.

Gibson widely uses Corian nuts. They generally do not age in appearance, keeping a fresh white look throughout their life.

Melamine is a chemical compound that is commonly used to produce strong plastic dinnerware, laminates, and glues. It’s also widely used as a nut material for Fender electric guitars.

This material handles similar to Graph Tech’s Tusq, but is perhaps a bit more brittle. We find the material chips fairly easily when being worked.

Delrin, is the brand name for a synthetic Polymer developed by the Dupont company. When marketed for use on guitar nuts and saddles it is also often called “slip stone“. This material is also a popular choice for guitar picks.

Nylon has seen occasional use as a guitar nut material, most notably by Gibson.

While it is touted as being slippery, nylon is also pretty soft and difficult to work with.

Ivory refers to material that was once an Elephant’s tusk. Prior to about 1970, Martin acoustic guitars featured ivory nuts and saddles.

Due to bans on its sale in 1980, and the obvious ethical issues that precipitated that ban, ivory is no longer commonly used.

For those inclined, fossilized walrus or mammoth ivory is the closest thing legally available.

Brass is an alloy of the metals Zinc and Copper. It is hard and durable.

Brass nuts are known for their brightness; They were a popular modification amongst some rock and metal guitarists in the 1970’s and 80’s.

With the exception of a few pro-model instruments, they are rarely seen as a factory original nut on a guitar. However, brass nuts are occasionally found on high end bass guitars.

Inexpensive instruments often come from the factory with a pre formed, molded plastic, nut. While these are cheap to mass produce, they are also soft, sticky, prone to wear and breakage, and do not produce the best tone.

These days, usually only the cheapest of instruments will have a molded plastic nut.

Mother of pearl, a common material used for inlays on instrument fingerboards and headplate logos, is occasionally seen as a nut material on high-end banjos.

Buffalo horn, ebony, graphite, etc. have all also see occasional use on musical instrument nuts and saddles.

What Nut or Saddle Material Sounds The Best?

Many guitarists are perpetually searching for shortcuts to a better sound; The endless tone quest. In our experience, the difference in tone between many of these materials is subtler than one might think. Furthermore: different is different, not necessarily better! Any perceived change in tone is subject to the particulars of the specific instrument and the player’s personal taste.

When replacement is necessary, our reasons for choosing one material over another are typically much more centered around durability, originality, or fitting a client’s desired aesthetic, than regarding any grand tonal difference between materials.

Should You Upgrade Your Nut?

When dealing with the nut, It’s important to remember that any tonal benefit of one material over another only applies to the instruments open strings. As soon as a string is fretted, the nut is largely removed from the tonal equation. With rare exceptions, whether or not a nut has been properly dressed and profiled is often more of an ‘x factor’ to the tone, tuning stability, and overall setup of an instrument than how, or from what material, the nut was made.

When it comes to nuts, we follow the adage of “If it ain’t broke, don’t fix it.” If your instrument has a nut that is worn or not fitted correctly, you would absolutely benefit from having it adjusted or replaced. After evaluation, the material chosen to replace it should then be selected based on the individual concerns of the instrument. However, we generally do not recommend the replacement of a perfectly serviceable nut made out of one material for one made from another.

Should You Upgrade Your Acoustic Guitar Saddle?

Since it affects all the notes of the instrument, a better argument can be made for replacing an acoustic guitar saddle on tonal grounds than the nut. A harder material may produce more volume and a brighter tone, whereas a softer one may be warmer and more subdued. However, being that the saddle is such a high traffic piece, this must be weighed against the fact that a soft material will not be as durable.

Erik Salomon - Calico Guitarworks Owner / Head Technician

Tech Talk articles are part of an ongoing effort to provide clear and detailed answers to common questions about guitar maintenance, modifications, and repairs.

While not intended as a step-by-step guide to servicing your own instrument, we hope that you will find value in the information provided.

Great Repairs Start With The Right Parts

Many of the parts mentioned in our blogs are available for purchase at:

GuitarRepairParts.com

Enter the code "TechTalk10" at checkout for 10% off your first order.

About Calico Guitarworks

Calico Guitarworks is the area’s premier destination for fretted musical instrument care and maintenance. Owned and managed by Erik Salomon, the shop is dedicated to providing quick, honest and reliable service. The staff at Calico Guitarworks has a combined 25+ years of professional guitar repair experience. Sharing the knowledge that we accumulate in this focused pursuit is at the core of what we do. Learn more About Calico Guitarworks, explore our Frequently Asked Questions, or Contact us with a specific request.