Taylor Guitars NT Neck Reset

Taylor Guitars has a well deserved reputation for modernizing the acoustic guitar. While many other brands have focused on recreating designs that have been around for over 100 years, Taylor Guitars is continuously innovating.

The brand is noteworthy for a host of achievements, including original body shapes that have become modern classics, patented expression system electronics, pioneering the use of UV cure finishes in guitar manufacturing, non-traditional “V class” internal bracing, and their work towards forestry conservation and sustainability. One of their crowning innovations is their patented NT Neck design. Though earlier models featured a hybrid neck joint, The Taylor NT neck was introduced in 1999 and has been a standard feature since 2001; It is considered a hallmark of the brand.

What Is The Taylor Guitars NT Neck?

Traditional acoustic guitar necks are joined to the body with glue, utilizing what is called a dovetail joint. As a result, the upper portion of the fingerboard is unsupported and glued directly to the top of the guitar.

The Taylor NT guitar neck is built from a continuous piece of wood that supports the ebony fretboard all the way up to the 19th fret and sits securely in a custom-fit pocket that is inset with laser-cut spacers.

Traditional guitar necks lose support at the body joint, relying on a fingerboard extension that is glued directly to the top. Accordingly, traditional necks may bend, literally hinging at the body. Taylor Guitar’s necks are designed to remain perfectly straight and stable.

Adjustability is another major advantage of the Taylor NT guitar neck. Altering the neck angle of a traditional dovetail neck assembly requires invasive surgery to remove the neck and reshape the joint. However, since the neck angle of a Taylor NT neck is created by spacers and requires no glue, an adjustment requires just a few minutes. The process is similar to the way we reset a bolt-on electric guitar neck.

Resetting a Taylor Guitars NT Neck: Step by Step

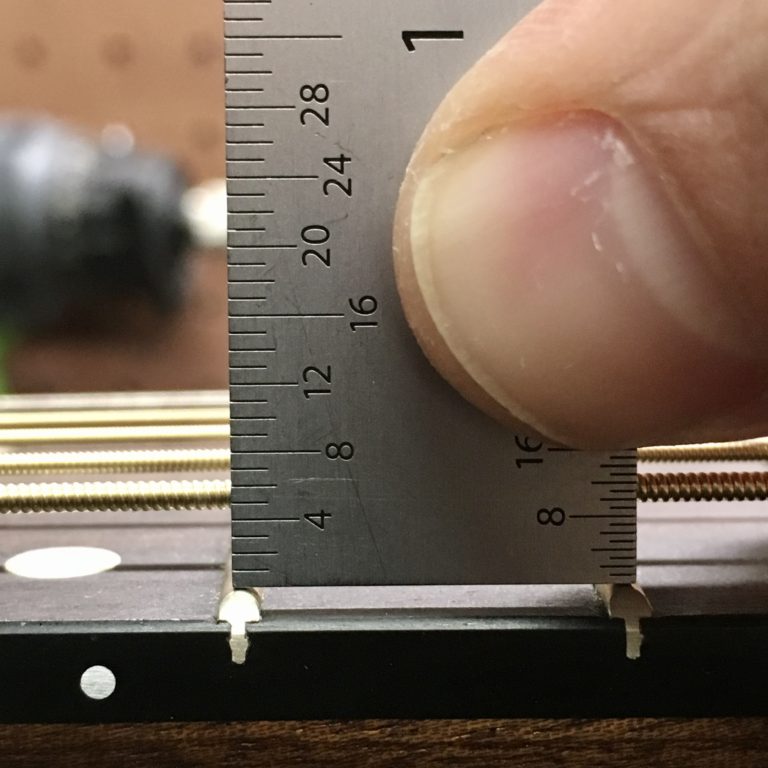

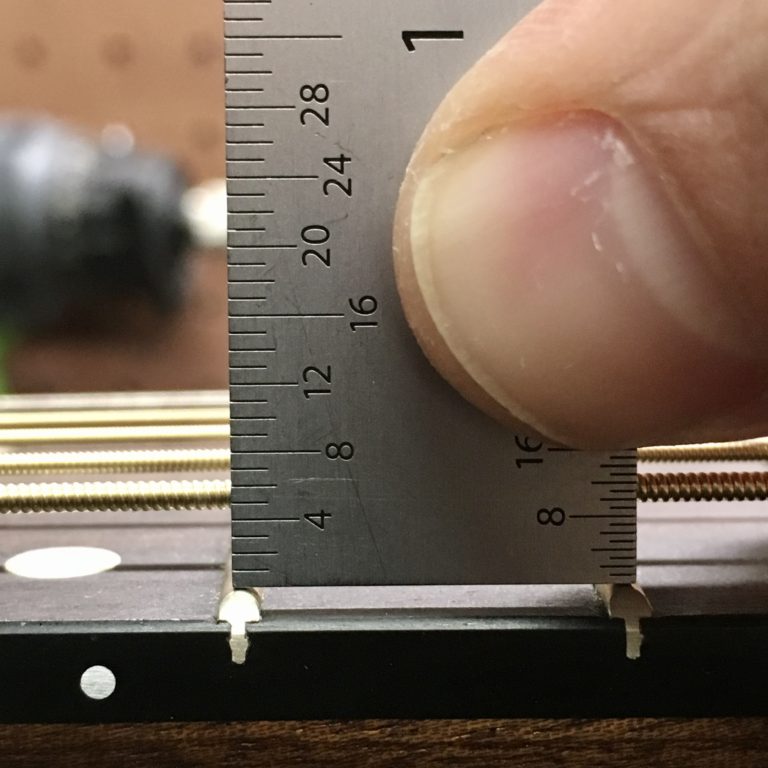

The guitar pictured was brought into the shop with a very high string action. It measured nearly 5/32″ at the 12th fret, almost double Taylor Guitars factory specified string height!

After performing a thorough evaluation, including a check of the instrument’s humidity level, we determined that the guitar’s action could not be sufficiently lowered through a typical setup alone. A neck reset was required for optimal performance from the instrument.

Calico Guitarworks is the areas top Taylor Guitars factory authorized service center

The job requires proprietary parts and should only be performed by a certified technician. The shims are not available for sale to the public.

Taylor NT Neck Removal

Inside of the guitar, three bolts attach the neck to the body. Two are located on the heel and are accessed by removing a decorative label. The third is located under the fingerboard extension.

Upon removing the neck from the body, the spacer shims become plainly visible in the neck pocket. One is positioned to rest against the heel while the other sits under the fingerboard extension.

Changing Shims to Adjust The Neck Angle

Taylor Guitars service department provides us with proprietary tapered shim sets for the heel and fingerboard extension.

These laser cut shims are used to adjust the angle at which the neck joins the body. Increasing the shim’s number raises the neck angle, thereby lowering the string height, while decreasing would raise string height.

Reinstalling The Neck

Dialing in an ideal shim combination to reach a desired action occasionally takes a bit of trial and error. Fortunately, it is simple to repeat the procedure with a different set until the desired results are achieved.

Taylor factory specification calls for a measurement of approximately 3/64″ at the high E and 5/64″ on the low E when measured at the 12th fret.

Once the correct angle has been achieved, we adhere a new label to cover the neck bolts. This guitar is now ready for final setup before heading back to its owner.

Taylor Guitars Heel "Crack"

Now and then, Taylor guitars present with a gap along the neck joint or fingerboard extension. While this may look like a crack, it is actually nothing to be alarmed about.

The design of the NT neck requires that some space be left to allow for future adjustment of the neck angle. At the factory, these small voids are filled with a special putty designed to camouflage them.

Occasionally, climate fluctuations, or a neck reset, may cause the putty to dry and flake out.

Closing The Gap

To repair it, we simply mix up some “neck putty” to Taylor Guitars’ specifications and wipe it into position. Once dry, it blends in quite nicely.

Erik Salomon - Calico Guitarworks Owner / Head Technician

Tech Talk articles are part of an ongoing effort to provide clear and detailed answers to common questions about guitar maintenance, modifications, and repairs.

While not intended as a step-by-step guide to servicing your own instrument, we hope that you will find value in the information provided.

Great Repairs Start With The Right Parts

Many of the parts mentioned in our blogs are available for purchase at:

GuitarRepairParts.com

Enter the code "TechTalk10" at checkout for 10% off your first order.

About Calico Guitarworks

Calico Guitarworks is the area’s premier destination for fretted musical instrument care and maintenance. Owned and managed by Erik Salomon, the shop is dedicated to providing quick, honest and reliable service. The staff at Calico Guitarworks has a combined 25+ years of professional guitar repair experience. Sharing the knowledge that we accumulate in this focused pursuit is at the core of what we do. Learn more About Calico Guitarworks, explore our Frequently Asked Questions, or Contact us with a specific request.